G.J. Kleisterlee

Ontwerpen van een hydraulische sproeikopaansturing.

Internship,

Report 2003.TL.6698, Transport Engineering and Logistics.

Company Vestergaard manufactures mainly de-icers and in the company's strive

for constant product improvement the actuating system of the nozzle had to be

enhanced. The nozzle, spraying a mix of water and glycol, is fixed at the

end of a boom and its motion is controlled by two hydraulic actuators.

Movement of the nozzle to left and right (horizontal plane) causes too

much wear and becomes inaccurate after intensive use. Moreover, the management

believes that integration of parts on this actuating system can reduce assembly

time and save costs when production is outsourced. Altogether reason for the

company to reconsider the current design of the system.

The main problem appeared to be the large forces on the joints of connecting

rods transmitting a translation of the hydraulic cylinder in to a rotation of

the nozzle. After intensive use these joints started to show too much margin.

A new design should improve durability, quality and functionality. In the

first stage of the project the objective was to develop a new hydraulic

actuating system to generate the movement of the nozzle. This new design had

to show less wear and slack after intensive use than appears on the current

actuating system. It had to be an overall improvement. During the project

increasing emphasis was put on the integration of as many parts possible. The

main reason for this was to simplify assembly and reduce costs. The production

of the part will be outsourced to a neighboring factory. This includes

advantages as good communication and no transportation costs. All these aspects,

in favour of integration of parts and outsourcing of production, had great

influence on the design.

First the performance of the current design had to be determined as a

starting-point for a new design. The force and speed of the hydraulic

cylinder and the reaction of the nozzle to a certain input speed at the

cylinder were established. This implies that the response of the nozzle

movement, in terms of angular velocity, to a constant speed of the piston

of the hydraulic cylinder was calculated. Some tests were run as well to

verify the forces involved and the actual force used to rotate the nozzle.

Subsequently some new concepts were considered and evaluated. Ultimately a

concept was chosen whereby two hydraulic cylinders were integrated in the

swing-axle on which the nozzle and hydraulic cylinder are presently

mounted. During the design process it became clear that the costs involved

in this concept were too high and a new solution had to be considered.

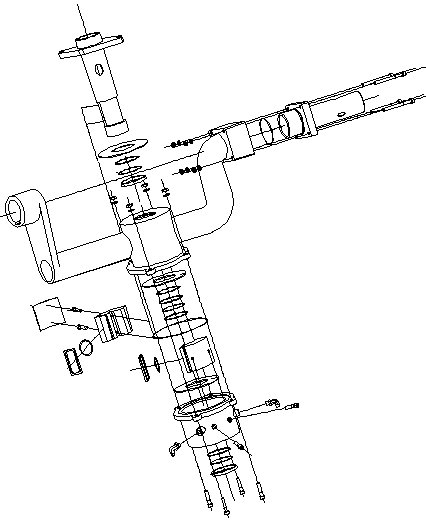

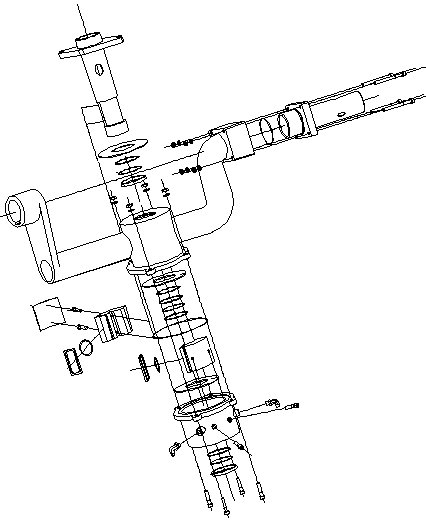

With the integration of parts as a strong condition the final design

became a hydraulic vane type rotary actuator integrated in the swing-axle

(figure I). The swing-axle is designed to cast out of stainless steel and

use CNC afterwards to finalize it. The vane motor uses two circular

pistons to rotate the nozzle. One piston is fixed to the housing and the

other one to the shaft mounted to the nozzle. By pumping hydraulic oil

in-between these two circular piston blocks they start moving away from

each other and consequently the nozzle starts turning. The volume flow and

the forces involved were optimized in comparison with the current design

by using the test results and calculations made earlier. Technical

drawings of the new design were made as well as 3 dimensional models and

sent to some manufacturers for cost evaluation. Eventually the cost was

estimated not to be higher than the costs involved with the current

design. Calculation on the weight of the integrated parts pointed out that

it will be 2 kilograms lighter than the 4,4 kg the swing-axle and hydraulic

cylinder are weighing together at the moment. When testing demonstrates that

the new design functions well, the performance has also been improved since

the rotation of the nozzle is proportional to the oil pumped in the actuator

and the speed is proportional to the oil flow (in m3/s).

Figure I: Exploded view of the final concept for an actuating system for

rotation of the nozzle spraying a de-ice fluid.

An enlarged picture of his exploded view can be found in the

appendix of the report where a partlist is added explaining all the parts.

Reports on Transport Engineering and Logistics (in Dutch)

Modified: 2003.11.29;

logistics@3mE.tudelft.nl

, TU Delft

/ 3mE

/ TT

/ LT.