B.C. Bührmann

Chemicaliëntransport in de 21ste eeuw.

Computer program,

Report 2003.TL.6746, Transport Engineering and Logistics.

Introduction

During a portcall, a parceltanker visits several terminals (average: four

terminals) to load or discharge chemicals. These chemicals can be

transhipped to a tank at a terminal or to another vessel, a barge or a

coaster. Due to a poor organisation of the transportation and different

interests between terminal operators and shipowners parceltankers stay in

port for a long time (average nine days), which affects the profitability

of the parceltankers in a negative way.

Loading and discharging the parceltanker at one location only (central

terminal) can reduce porttime. The cargo that has a terminal as the final

destination is transhipped into a smaller vessel and transported to the

terminal. These actions result in extra costs, because of the extra

transhipment, transport and cleaning of tanks. On the other end the yearly

profits of a parceltanker could rise, as the porttime of the parceltankers

is reduced to a couple of days. The model described in this report

determines whether the extra profits counterbalance the extra cost for

transportation. Although the model can be used for al kinds of

parceltankers, ports and liner services, there has been chosen for one of

the largest parceltankers (37.015 dwt), which runs a weekly service

between Houston and Rotterdam.

Model on port level

The model consists of two levels for calculations, port level and chain

level. First of all the costs of a stay in port are calculated with the

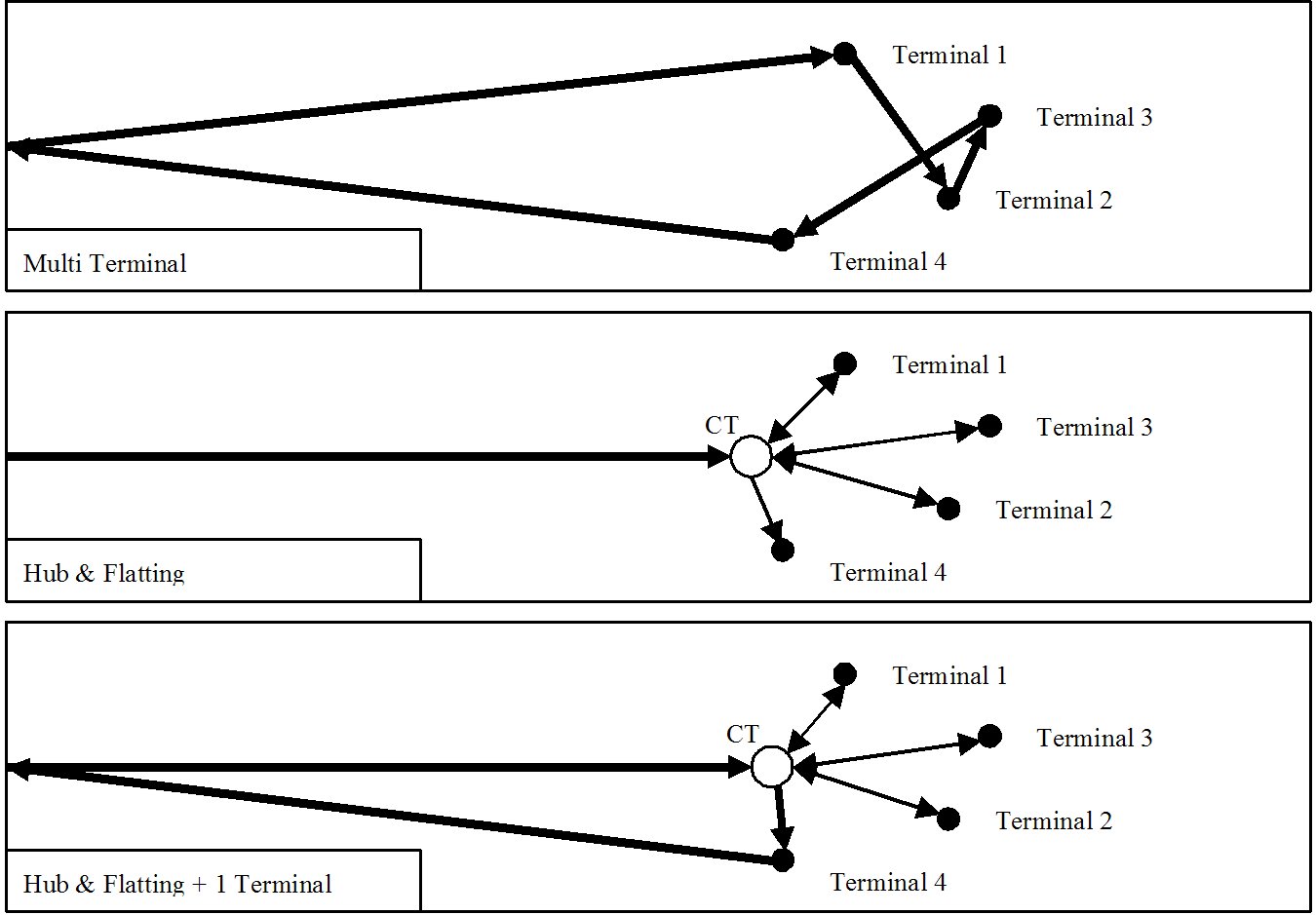

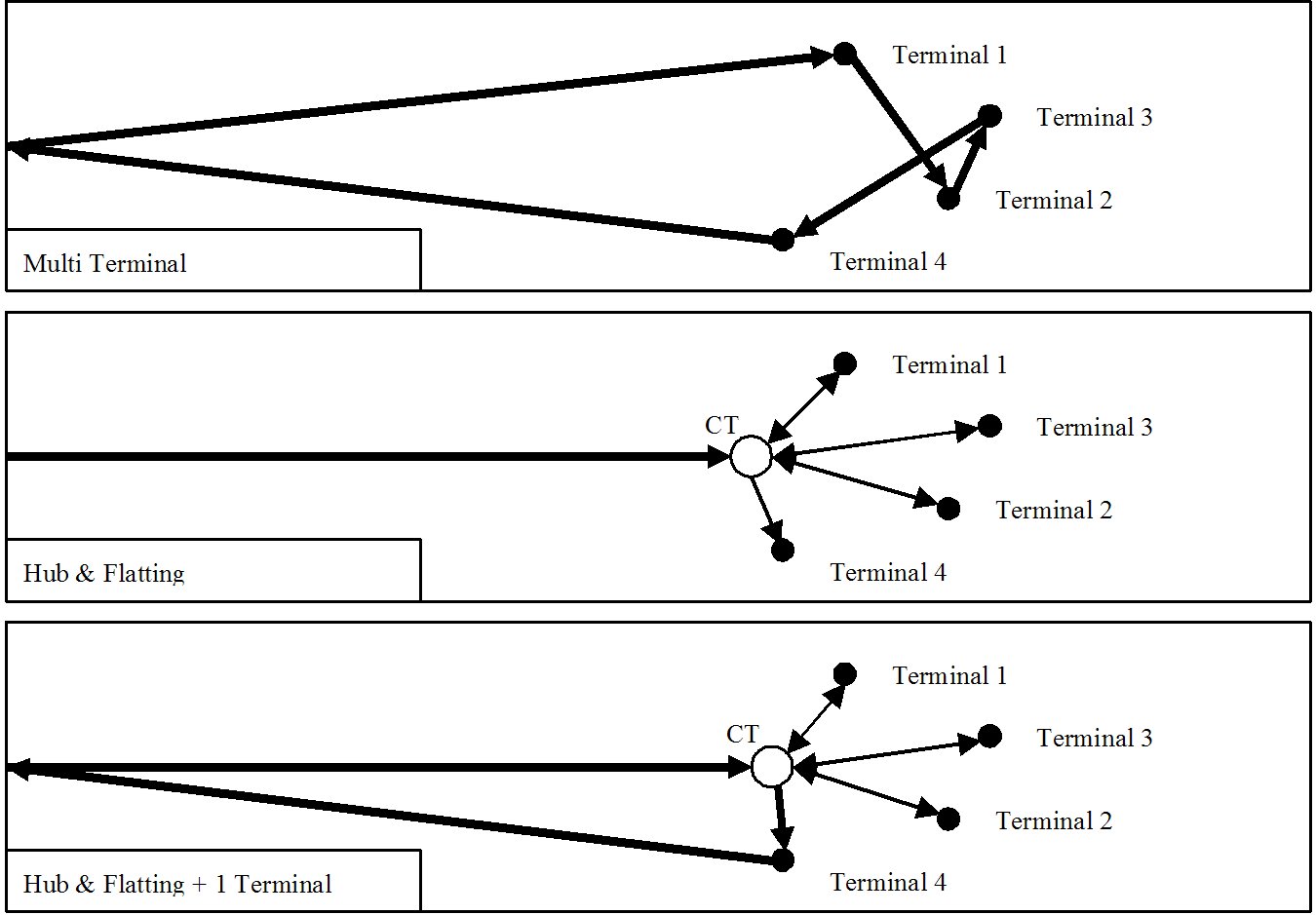

model on port level. Three concepts are developed for the transhipment of

chemicals (see figure 0-1):

Figure 0-1: Three used concepts

- Multiterminal: the parceltanker visits 4 terminals and stays in port

for 9 days

- Hub & Flatting: the parceltanker visits the central terminal only

and stays at the terminal for 2 days

- Hub & Flatting + 1 terminal: the parceltanker visits the central

terminal and is shifted to another terminal to tranship a big amount of

cargo and stays in port for three days.

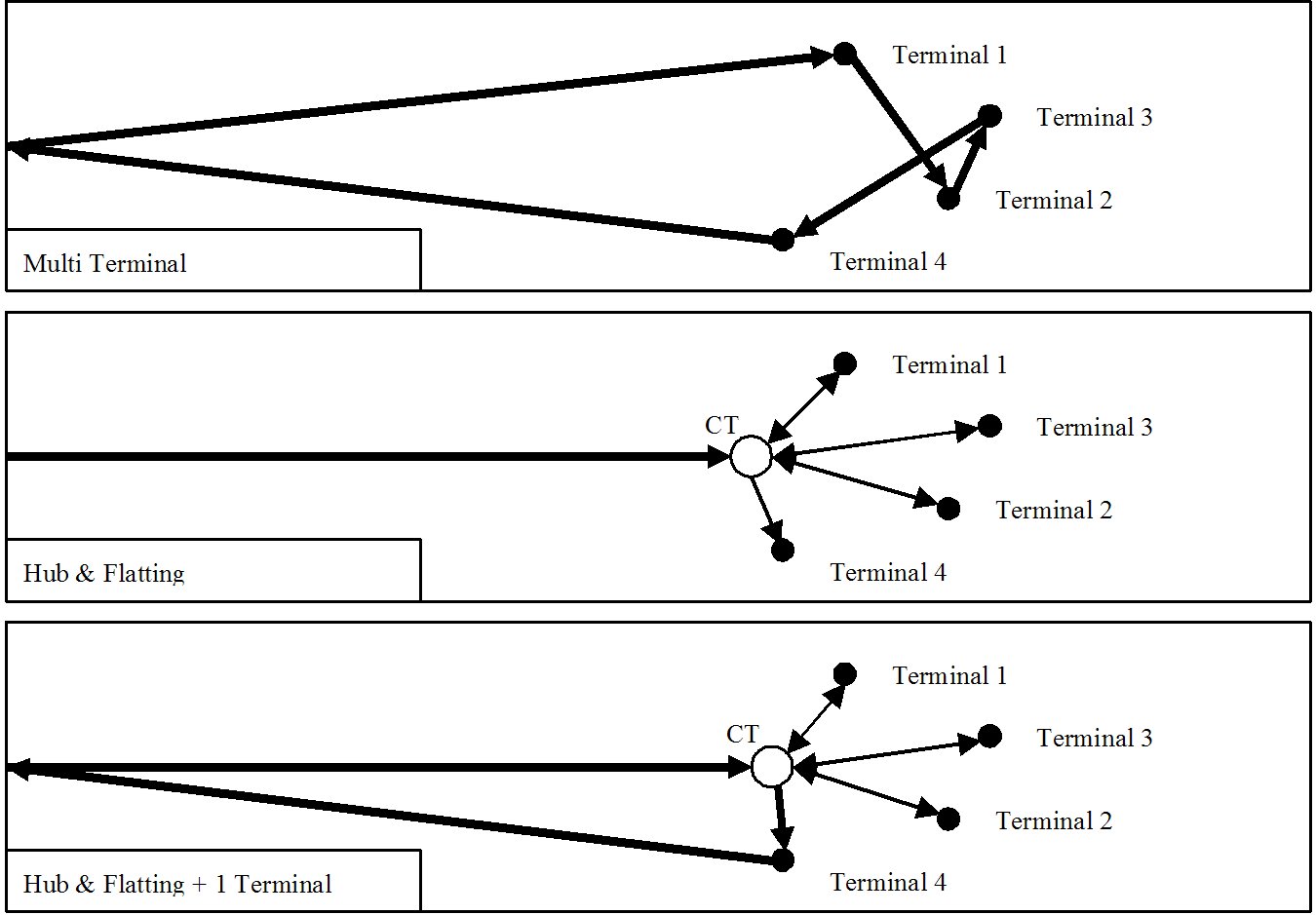

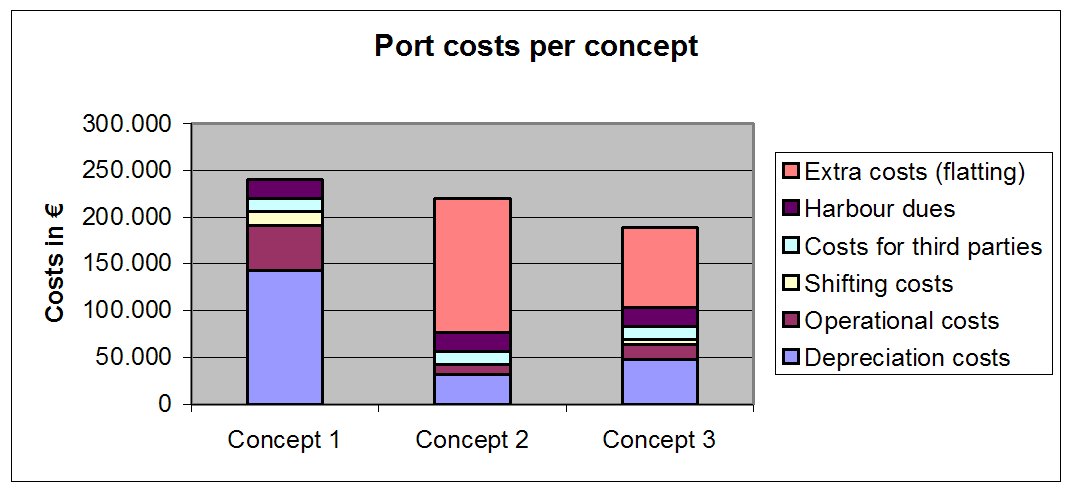

In figure 0-3 the results are given for the model on port level. The

results show the different kind of costs during a stay in the port of

Rotterdam.

Figure 0-2: Portcosts per concept

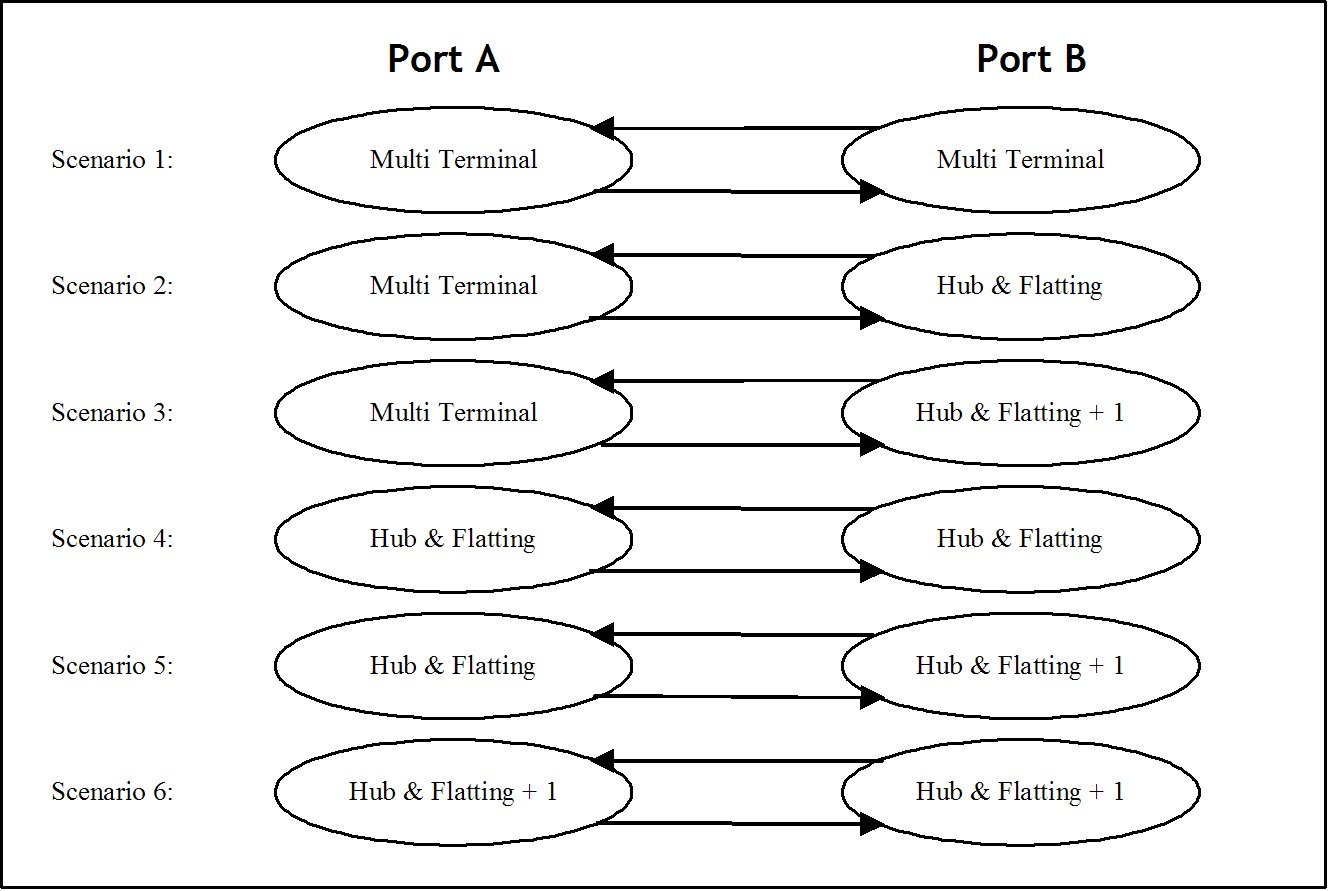

Model on chain level

To determine the consequences of a shorter stay in port on the

profitability of the parceltankers the model is extended to chain level.

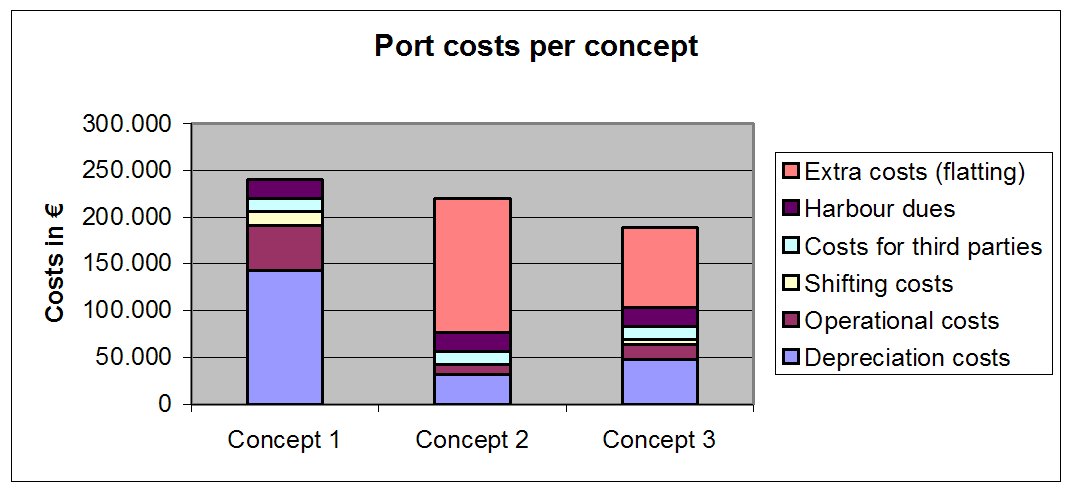

The three different concepts are employed on the ports of Houston and

Rotterdam, between which a service is held with weekly departures. A

combination of two concepts forms a scenario a total six scenarios are

possible. Scenarios 2 till 6 are compared with scenario 1, which

represents the present situation of the transportation of chemicals.

Figure 0-3: Six scenarios

Results

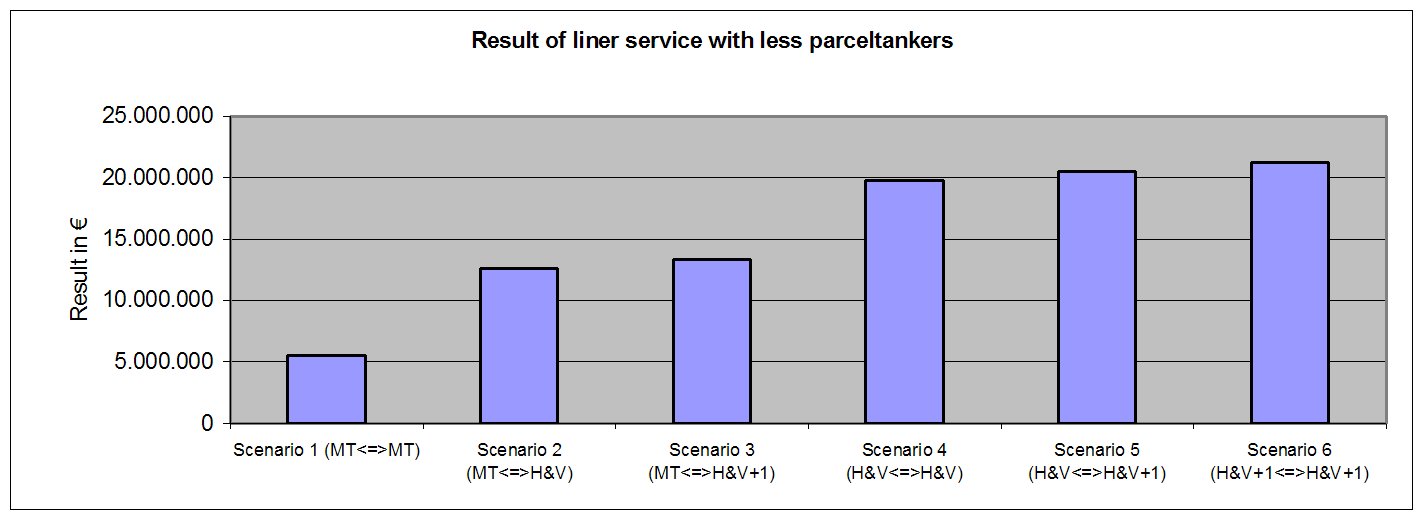

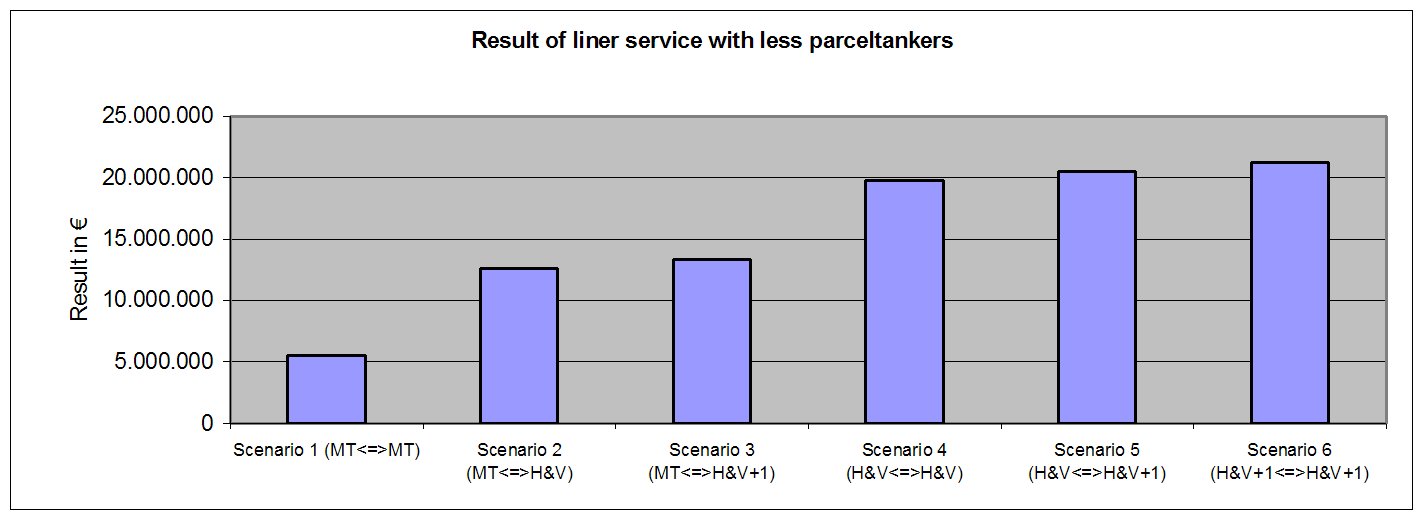

The physical results are calculated for each scenario before the financial

results are given. The physical results consist of the percentage

porttime, the amount of parceltankers needed to run the liner service and

the yearly amount of departures for every parceltanker. The financial

results are given for each departure of a parceltanker, for every single

parceltanker and for the liner service in total. It seems that with a

shorter stay in port less parceltankers are needed to run the liner

service. The parceltankers that remain can be used in other regions. The model

is based on a new liner service. The savings on the depreciation costs are

added to the result (see figure 0-4).

The results of the scenarios, where parceltankers are transhipped at a

central terminal in both ports, hardly differ and are much better than the

result in the present situation.

Figure 0-4: Result liner service with the influence of less parceltankers

Sensitivity analysis

It is expected that in the future the percentage of direct transhipment to

another vessel will rise. Therefore there has been checked what the

consequences of this affect are in the future. As expected the

implementation of a central terminal shows better results, because less

cargo has to be transported extra. The use of smaller parceltankers could

reduce the differences between scenario 2 till 6 and the present situation

if the occupancy rate of the parceltankers increases. A liner service

between two ports (Rotterdam and Singapore) that are situated further away

from each other, also reduces the differences between the scenarios. Finally

the model is tested for the situation, where transhipping equipment is taken

from the parceltankers and placed at the central terminal. The results give

reason for further research.

Conclusion

The model used for calculations on port level shows that the implementation

of a central terminal saves costs during a stay in a port. On chain level the

model shows that the profitability of parceltankers rises.

Reports on Transport Engineering and Logistics (in Dutch)

Modified: 2003.11.29;

logistics@3mE.tudelft.nl

, TU Delft

/ 3mE

/ TT

/ LT.