F.G. Giebel

Massareductie op de horizontale transportwagen van de "Carrier Crane".

Literature survey,

Report 2003.TL.6820, Transport Engineering and Logistics.

After a short introduction about the subject it is explained why the ship shore

container crane "Carrier Crane" has been developed. There is the answer to the

question "How to realize mass reduction on the horizontal container

carrier", which is important for the structural dimensioning of the

"Carrier Crane".

The global market for the transportation of sea freight containers is

still growing and this will result in larger and more cost efficient

vessels. The conventional ship shore cranes which are being used today are

most likely not able to fulfill the requirements needed in the future.

This is the reason why the section Transport Technology has developed a

new type of ship shore container crane. This "Carrier Crane" is

capable to load and to unload a Ultra Large Container

Ship with an operational capacity of 65 moves/hour.

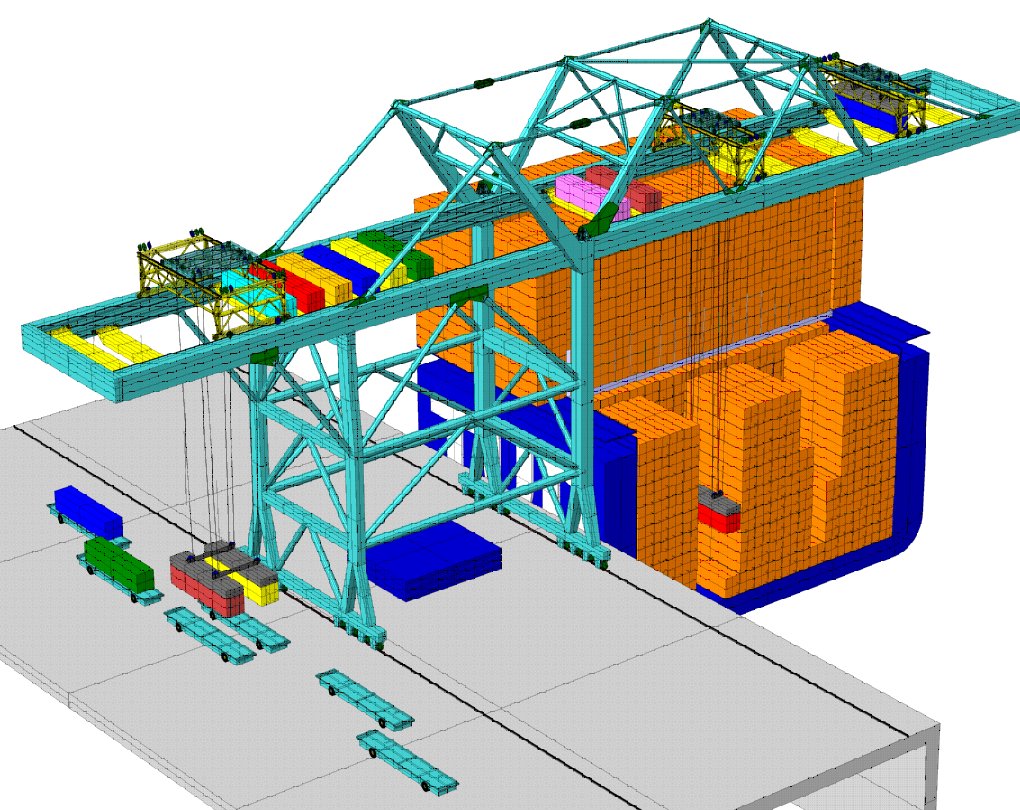

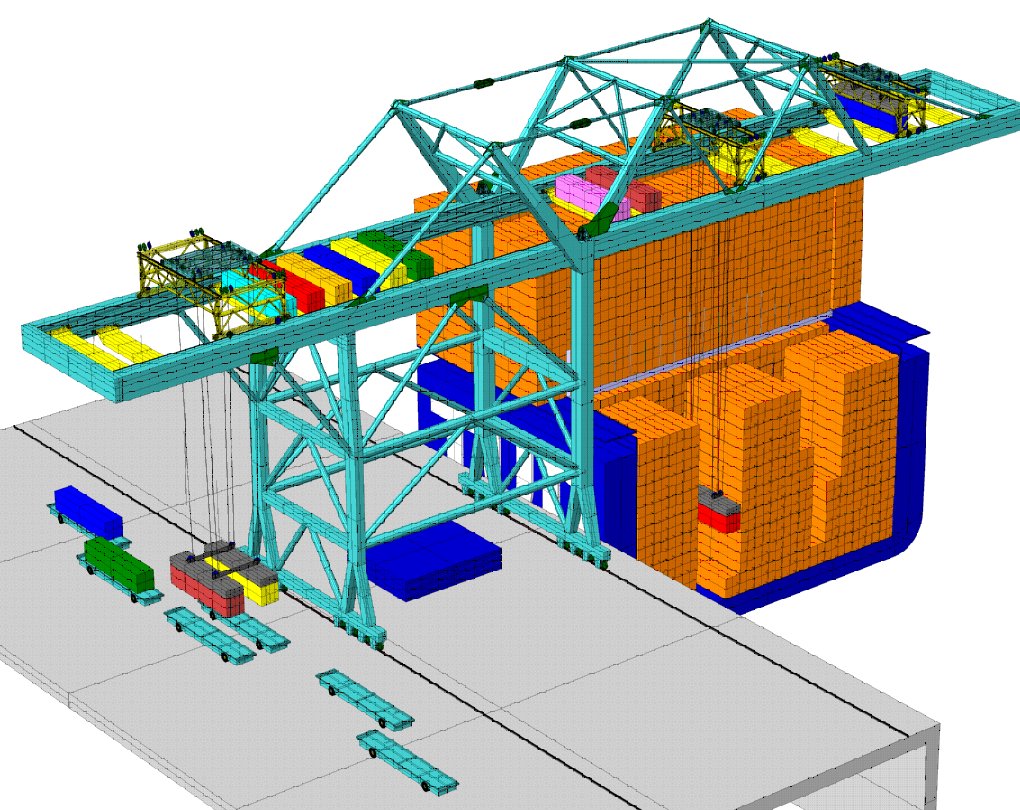

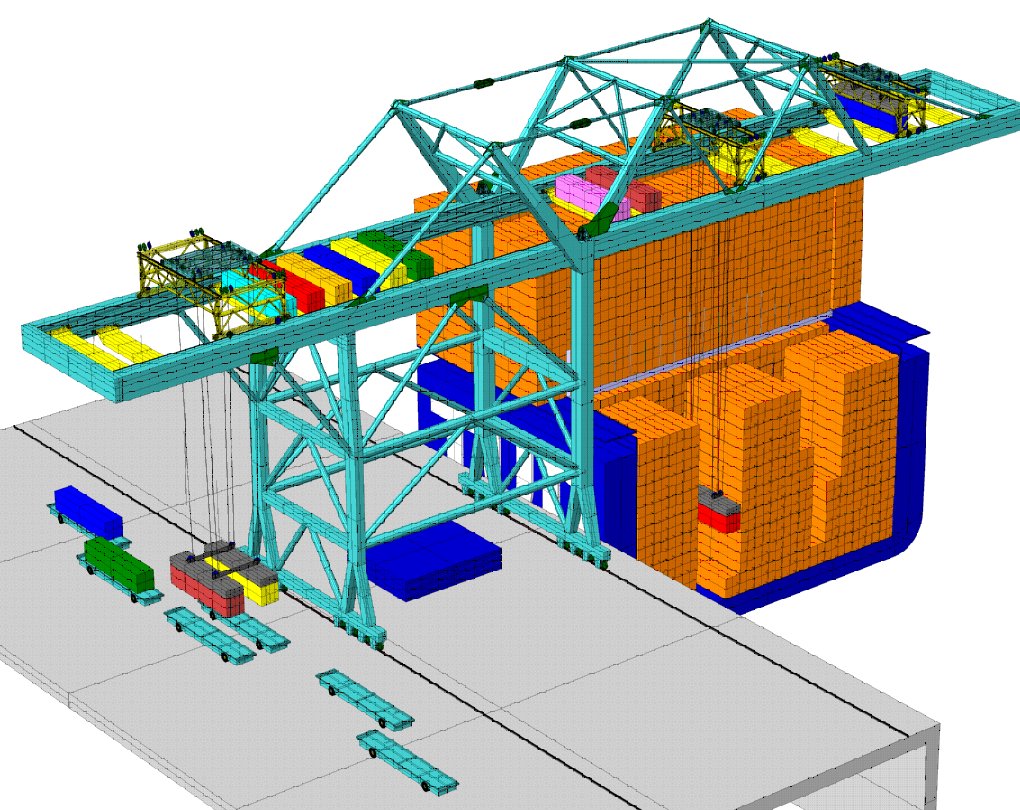

Figure 1 Basic design "Carrier Crane".

The working principle of the "Carrier Crane" for the procedure of unloading a

container ship is explained in figure 1. One of the two vertical transportation

systems, which are in position for picking up a container from the vessel,

lifts the container. On the instant that the container is fully risen a

horizontal container carrier drives underneath. After detaching, the container

is transported to the back of the crane. The containers are temporarily

queued up and waiting for descending. At each move of the vertical

transportation cycle two containers are places on an Automatic Guided

Vehicle.

Because there are a number of sixteen horizontal container carriers

traveling in the extremities of the boom and girder a minimum of mass of a

horizontal container carrier is desirable. The purpose of this report is

to investigate the possibility of mass reduction of the horizontal

container carrier. This objective is realized by significant mass savings

by the following topics.

- Alternative structural design

- Introducing high strength steel, aluminum or composite materials.

- Replacing horizontal container carriers before the end life of the

"Carrier Crane". Hereby eliminating durability as a design criterion.

The realization of these objectives results in eight possible designs.

The mass is reduced from the preliminary estimation of 10 ton to

approximately 6 ton. Mass reduction is mainly accomplished by two

different types of reasons.

- Crossing of the horizontal container carrier

All in this report proposed solutions are suitable for the crossing of the

horizontal container carrier. They all comply to demands such as strength,

stiffness and durability which are specified in international standards.

Further calculations must be made to insure the safety on stability. The

final choice can be made on other grounds than construction safety. Such

grounds are for instance the choice of that the hole structure must be

made out of the same material. Or that all welds made with special

quality should be eliminated.

- Wheels

In this mass of 6 ton the weight of the crane rails is included. This is

done by dividing the total weight of the crane rails through the number of

horizontal container carriers. When polyamide wheels are being applied on

the horizontal container carrier there is no need for a crane rails. The

only problem is that practical applications and references are not yet

available. So it is necessary to do a test with this type of wheel.

In my personal opinion the application of a construction build from hollow

rectangles 100*100*6,5 with the material Fe 510 and welds of special quality

is best likely to fulfill the requirements stated in the report, although this

configuration does not differ a lot from the other seven stated solutions. All

eight proposed solutions are checked by international standards to ensure

enough safety for strength, stiffness and durability. The control calculations

for stability are not preformed in this report. That includes calculations for

eigenvalue problems. So this is something that also has to be done before

taking further action.

As a consequence of these mass reductions on the horizontal container

carrier the structure of the "Carrier Crane" can be optimized.

Real mass reductions can be expected and this will reduce forces on the

corners of the crane, the rail and quay. So it can be concluded that the

realization of the "Carrier Crane" is one step further to application in real

life.

Reports on Transport Engineering and Logistics (in Dutch)

Modified: 2003.12.24;

logistics@3mE.tudelft.nl

, TU Delft

/ 3mE

/ TT

/ LT.