W. Wang

Design of a container terminal in Ningbo Port China

Engineering Assignment,

Report 2007.TEL.7193, Transport Engineering and Logistics.

The port of Ningbo is one of the most important and busiest portsin mainland

China, located in the mid-China's coastline, and on the south side of

Hangzhou Bay. Furthermore, there is a short distance from Ningbo to HongKong,

Kaohsiung, Pusan, Osaka and Kobe. All these features would make this port an

ideal choice among terminal operators to build up a container terminal and

develop sea-going shipping with America, Europe, the Middle East and Oceania.

Considering the port history of around 1200 years, Ningbo has a relatively

matured transport networks and developed hinterland connection which would

increase its predominance in the competition among China's ports. Additionally,

in recent years the port authority has strengthened the port constructions and

has improved facilities, environment and corresponding services to facilitate

for container terminal. As a result, the yearly throughput of the port in 2006

is 7 million TEU, and then Ningbo ranks among the top-5 ports of mainland

China and the top-15 ports of the world.

The objective of this assignment is to design a container terminal in the

port of Ningbo which will have a yearly throughput of 1 million containers,

in which imported and exported container capacity both are 500,000 boxes.

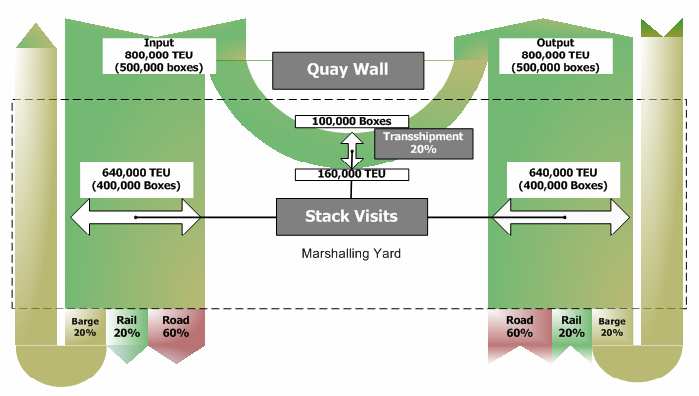

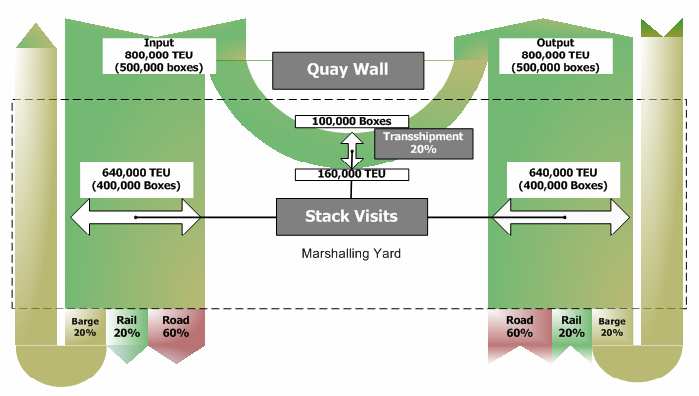

Among which, 20% of all moves that produced from sea-going vessels was

direct transshipment, namely 100,000 boxes per year; and the rest would be

divided into 60% for roadway, 20% for barge and 20% for railway. The TEU

factor is 1.6, then the container throughput presented by 'TEU' is 1,600,000

TEU. In addition, the maximum call size for berthed container vessels

with a capacity of 10,000 TEU (See Figure 1).

Figure 1: Container flow condition in this project

For the design of this container terminal, firstly a conceptual design was

considered, followed by the election of container handling system and the

main design of stacking yard, other facilities was designed in the next part.

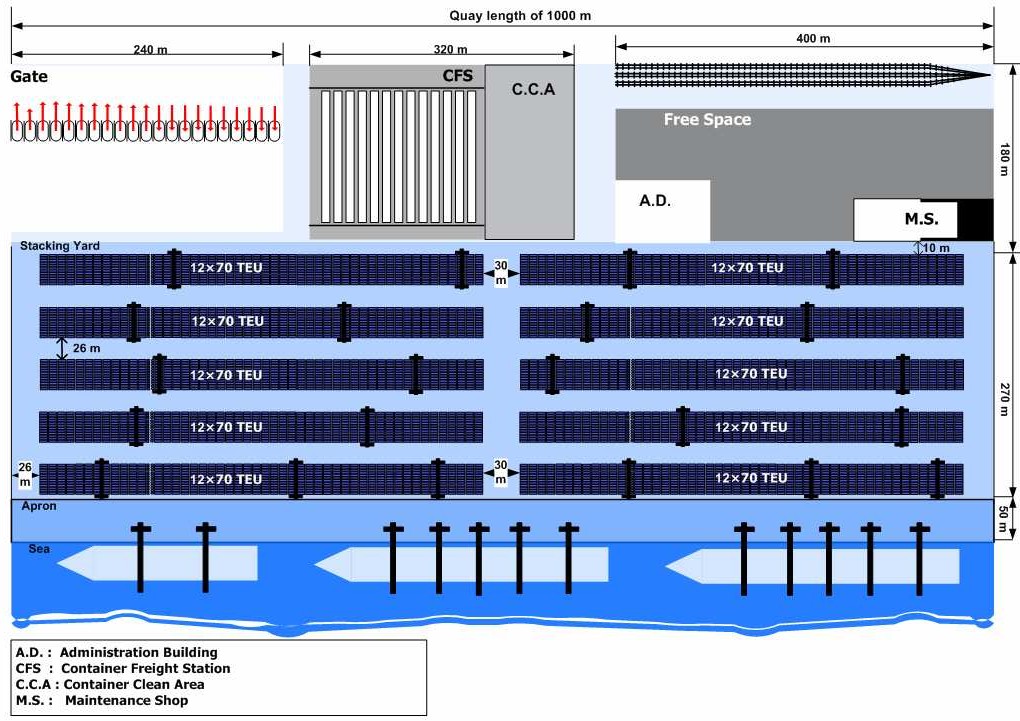

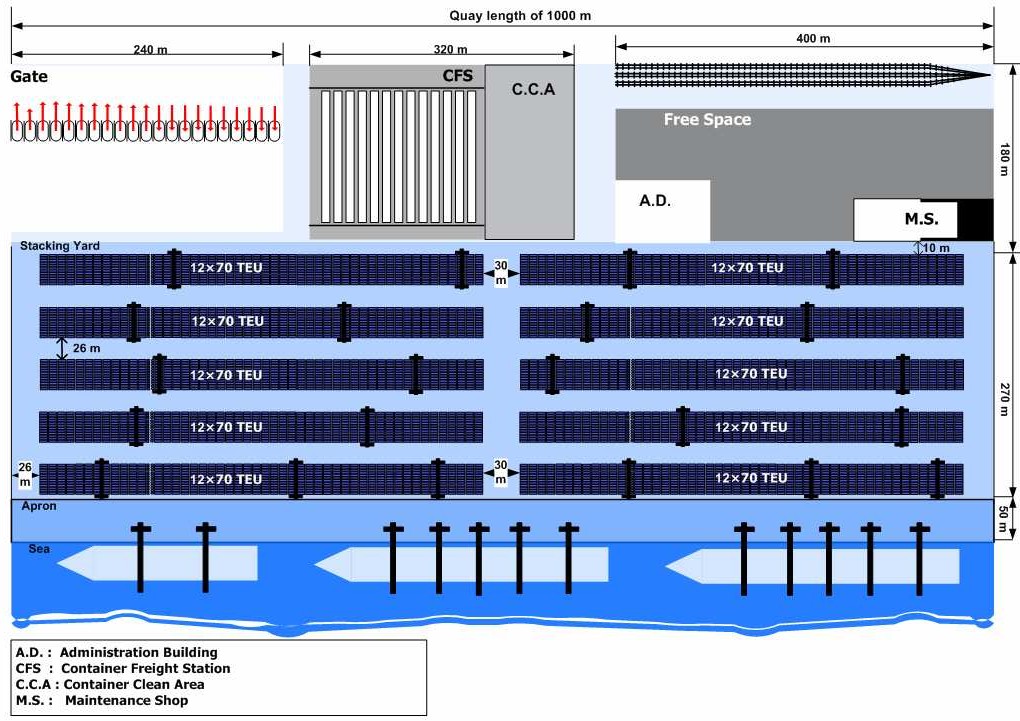

A final design of the container terminal was shown as Figure 2, such as

1000m of quaywall length, 50m of apron width, and 12 of quay cranes. For the

stacking yard, RMG (rail mounted gantry crane system) with terminal trailers

would be selected from OC (On-chassis system), SC (Straddle carrier system).

Additionally, the number of gate facilities would be 30 and the number of

bays in the Container Freight Stations would be 40. The total area of this

container terminal is 500m×1000m.

Figure 2: Final Layout of Ningbo container terminal

Recommendations:

The design of gate system should be improved according to the practical

arrival rule of road trucks.

The design of administration building would be finished after all employees

would be decided, so its area should be adjusted.

In addition, simulation of this design would be required in order to measure

all these data are feasible or not.

Reports on Transport Engineering and Logistics (in Dutch)

Modified: 2008.01.31;

logistics@3mE.tudelft.nl

, TU Delft

/ 3mE

/ TT

/ LT.